By Louis Cammarosano

Under the Coin Modernization, Oversight, and Continuity Act of 2010 (the “Act”), the U.S. Mint (the “Mint”) has been tasked by Congress to “conduct research and development on alternative metallic materials for all circulating coins” and to review production methods that might result in cost savings.

The Mint produced gold coins for general circulation until 1933 when they were confiscatedand never produced again for general circulation.

Prior to 1965, the Mint produced dimes, quarters, half dollars and dollars for general circulation that were 90% silver and 10% copper. The Mint has ceased minting silver coins other than for collectors and investors. Dimes and quarters are now minted with 92% copper and 8% nickel. Half dollar and dollar coins are no longer minted for general circulation.

Prior to 1983, U.S. pennies were minted from 95% copper. Today’s pennies are now 97.5% zinc.

Only the nickel remains in its same form since 1866: 75% copper/25% nickel.

The trend over the past eighty years at the Mint has been to remove precious metals from coins and replace them with base metals, like copper and nickel. In the case of the penny, the copper has been removed and replaced with less expensive zinc.

Last week, the Mint issued

its biannual report to Congress (the “Report”) on their cost savings findings pursuant to the Act.

its biannual report to Congress (the “Report”) on their cost savings findings pursuant to the Act.

Debasement Doesn’t Provide Much Savings

The Report noted that the Mint has considered twenty nine different metal compositions and conducted extensive testing of a 80 percent copper and 20 percent nickel composition which they deemed to be the most promising because coins so composed would offer nearly idential weight and electro-magnetic signature (“EMS”) of existing coinage. Currently, nickels are made of 75% copper and 25% nickel. Since copper costs about 40% of the price of nickel, an increase in the copper content and decrease in the nickel content would lower the overall cost of coin production. The savings from mintage of such coins, however, is modest, just 3% or $5 millionusing 2013 coin production volumes.

Replace Copper and Nickel with Steel?

The Mint also tested five alternative metal compositions for future coin production including:

nickel plated steel;

multi-ply plated steel;

stainless steel;

copper plated zinc; and

tin plated copper plated zinc

multi-ply plated steel;

stainless steel;

copper plated zinc; and

tin plated copper plated zinc

The Mint determined that only the steel based alternatives provided acceptable durability. Lighter steel based coins could result in savings of about $57 million annually, but may be confused for lesser valued foreign coins in vending machines and parking meters. The Report noted that the Mint will not recommend adopting any of the alternative metal compositions until they complete ongoing research “on a promising alternative that has the potential to duplicate the weight and EMS of existing coinage.”

The Report’s ultimate recommendation was to punt and spend 2015 doing more research. The costs of such testing and research do not appear to be factored in (R&D amortization) the over all new cost of production, which would reduce any savings realized.

According to the Report, in 2013 the United States Mint produced over 10.7 billion coins for delivery to the Federal Reserve Banks and will produce 13 billion coins in 2014.

Set forth below are details regarding the coins that the Mint produces for general circulation, their history and possible new compositions:

The Penny

Current Penny:

Weight: 2.5 grams

Composition: 97.5% zinc 2.5% copper

Composition: 97.5% zinc 2.5% copper

Metallic value*: $0.0055401

Unit Cost of Penny Production 2013: $0.0166

Unit Cost of Penny Production 2014: $0.0241

Unit Cost of Penny Production 2014: $0.0241

2013 Mintage: 7,070,000,000

A penny currently has less than one cent in metallic value. In 2014, each penny cost approximately 1.7 cents to make down from nearly 2.5 cents in 2013. Increased production and a 6.9% decline in the price of copper year over year contributed to the lower cost.

Upside down production costs caused the Canadian Mint to cease producing pennies in 2012.

The Mint’s Report concluded that there is no practical way of decreasing the cost of producing the penny.

Pre 1983 Penny

Weight: 3.11 grams; composition 95% copper 5% tin/zinc

Metallic value: $.0189742

Midway through 1982, the United States Mint ceased production of pennnies that were made of 95% copper. These pennies have a current metallic value of nearly two cents.

1943 Steel Pennies

The steel penny minted only in 1943 relies on inexpensive steel and may serve as the prototype for future U.S. coinage.

In 1943, the United State Mint produced zinc coated steel pennies as copper was needed for the war effort. These pennies weighed 2.7 grams and have inconsequential metallic value.

The Nickel

Current Nickel:

Weight: 5 grams

Composition: 75% copper 25% nickel

Composition: 75% copper 25% nickel

Metallic Value: $0.0430218

Unit Cost of Nickel Production 2013: $0.1118

Unit Cost of Nickel Production 2014: $0.0809

Unit Cost of Nickel Production 2014: $0.0809

Nickels currently have a metallic value roughly equivalent to their five cent face value. Nickels cost over a dime to make in 2013 turning Yogi Berra’s quote “A nickel ain’t worth a dime anymore.” on its head.

Because the production cost of each nickel exceeds its face value, all six alernative metal compositions referenced above were tested on the nickel.

2013 Mintage: 1,223,040,000

The composition and weight of U.S. nickels has remained constant since 1866 other than from 1942-45 when, due to war time requirements for nickel in the production of munitions, the five cent piece was composed of 56% copper, 35% silver and 9% manganese.

The Silver War-Time Nickel

From 1942-45 nickels were made of copper, silver and manganese and contained no nickel. War time nickels were identifiable by a large mint mark (P, D or S for Philadelphia, Denver or San Francisco) engraved above the Jefferson Memorial on the reverse.

Metallic Value of War Time Nickels (1942-45): $0.8974

War time nickels have a metallic value of nearly $1 a piece.

The Dime

Current Dime:

Weight: 2.27 grams

Composition: 91.67% copper 8.33% nickel

Composition: 91.67% copper 8.33% nickel

Metallic value: $0.0160454

Unit Cost of Dime Production 2013: $.0565

Unit Cost of Dime Production 2014: $.0391

Unit Cost of Dime Production 2014: $.0391

2013 Mintage: 2,112,000,000

Current U.S. dimes have a metallic value of about one and a half cents. In 2013 they cost over a nickel each to make and in 2014 they cost under four cents each to make. Although dimes are composed of the same metal as nickels, they are are cheaper to produce because they are less than half the size and weight and contain less nickel.

Pre 1965 Silver Dimes

Weight: 2.50 grams;

Composition: 90% silver 10% copper

Composition: 90% silver 10% copper

Metallic value: $1.1538

Prior to 1965, U.S. dimes contained .07234 ounces of pure silver, or about 3/4 of a tenth of an ounce of silver. A silver dime today has a metallic value of about $1.15.

The Quarter

Current Quarter

Weight: 5.67 grams

Composition: 91.67% copper 8.33% nickel

Composition: 91.67% copper 8.33% nickel

Metallic value: $0.0401154

Unit Cost of Quarter Production 2013: $0.1114

Unit Cost of Quarter Production 2014: $0.0895

Unit Cost of Quarter Production 2014: $0.0895

2013 Mintage: 1.455,200,000

Current U.S. quarters have a metallic value of about four cents. They cost more than a dime each to make in 2013 and about nine cents each in 2014.

Pre 1965 Silver Quarter

Weight: 6.25 grams

Composition: 90% silver 10% copper

Composition: 90% silver 10% copper

Metallic value:$2.8845

Prior to 1965, U.S. quarters contained .18084 ounces of pure silver, or about two tenths of an ounce of silver. A silver quarter today has a metallic value of about $3.

The Mint ceased producing fifty cent and one dollar coins for general circulation in 2001 and 2011, resepectively.

*values from coinflation.com as of December 19, 2014

Mintage Numbers: The U.S. Mint and A Guide Book of United Stats Coins – R.S. Yeoman, 2015 edition.

Images: CanStockPhoto (other than the Silver nickel)

Mintage Numbers: The U.S. Mint and A Guide Book of United Stats Coins – R.S. Yeoman, 2015 edition.

Images: CanStockPhoto (other than the Silver nickel)

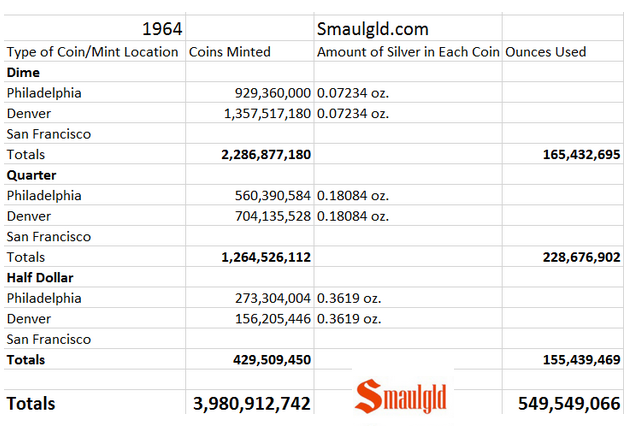

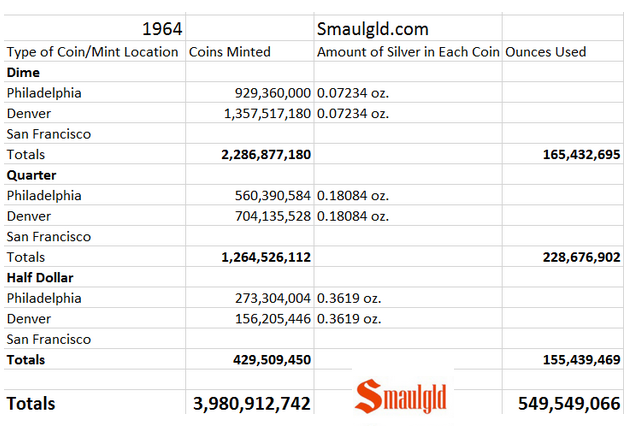

Perspective: While the Mint is feeling the pinch from higher base metal costs (copper and nickel) required to produce its coinage, in 1964 the Mint used 550 million ounces of the precious metal, silver, to produce dimes, quarters and half dollars for general circulation.

In 2014’s record year of production of American Silver Eagles, and in the production of America the Beautiful silver coins, the Mint used less than 50 million ounces of silver.

The United States Mint used over a half a billion ounces of silver to produce 1964 dated silver dimes, quarters and half dollars..

Ahhh devaluation,, gotta lovit

ReplyDelete